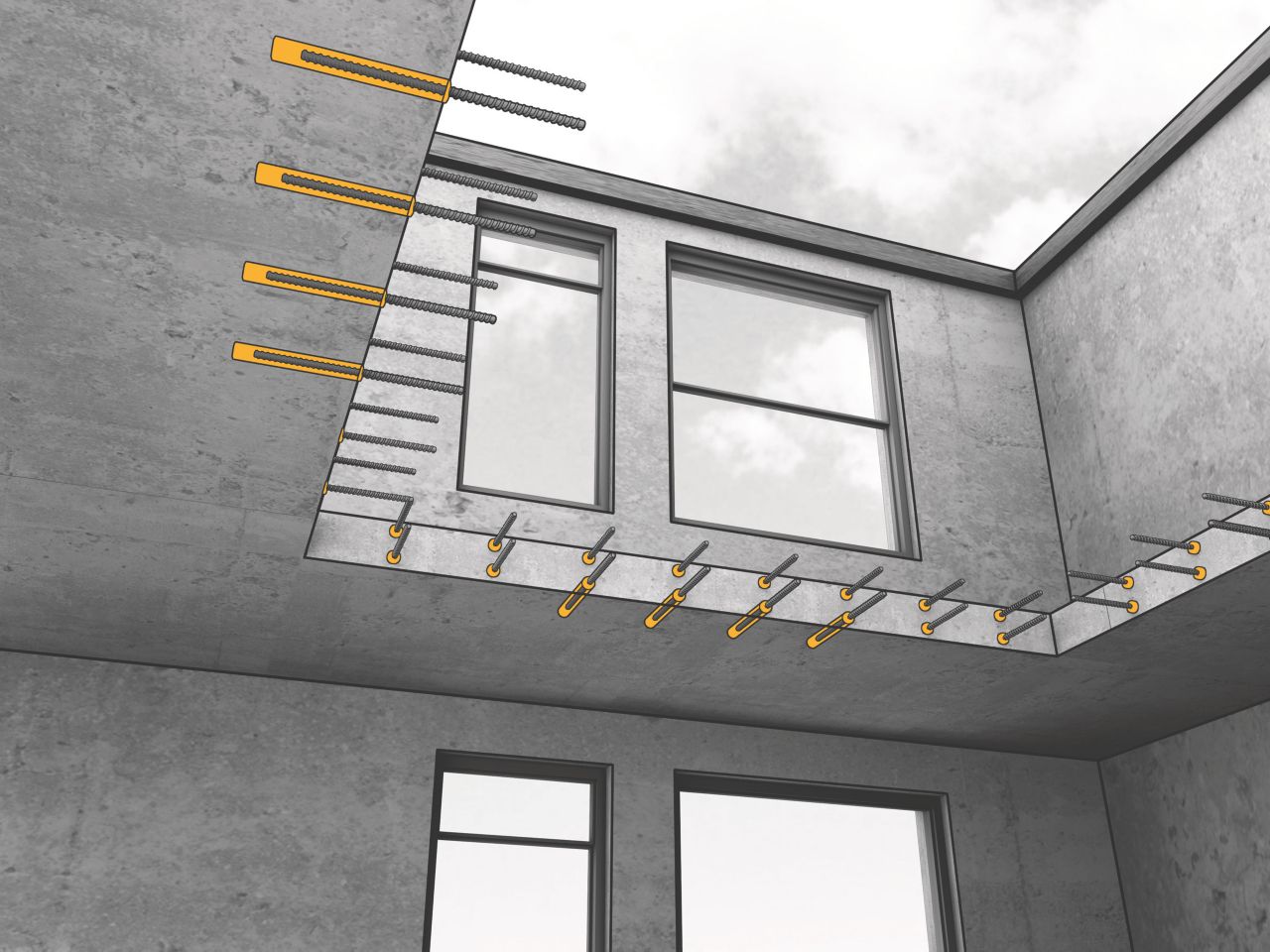

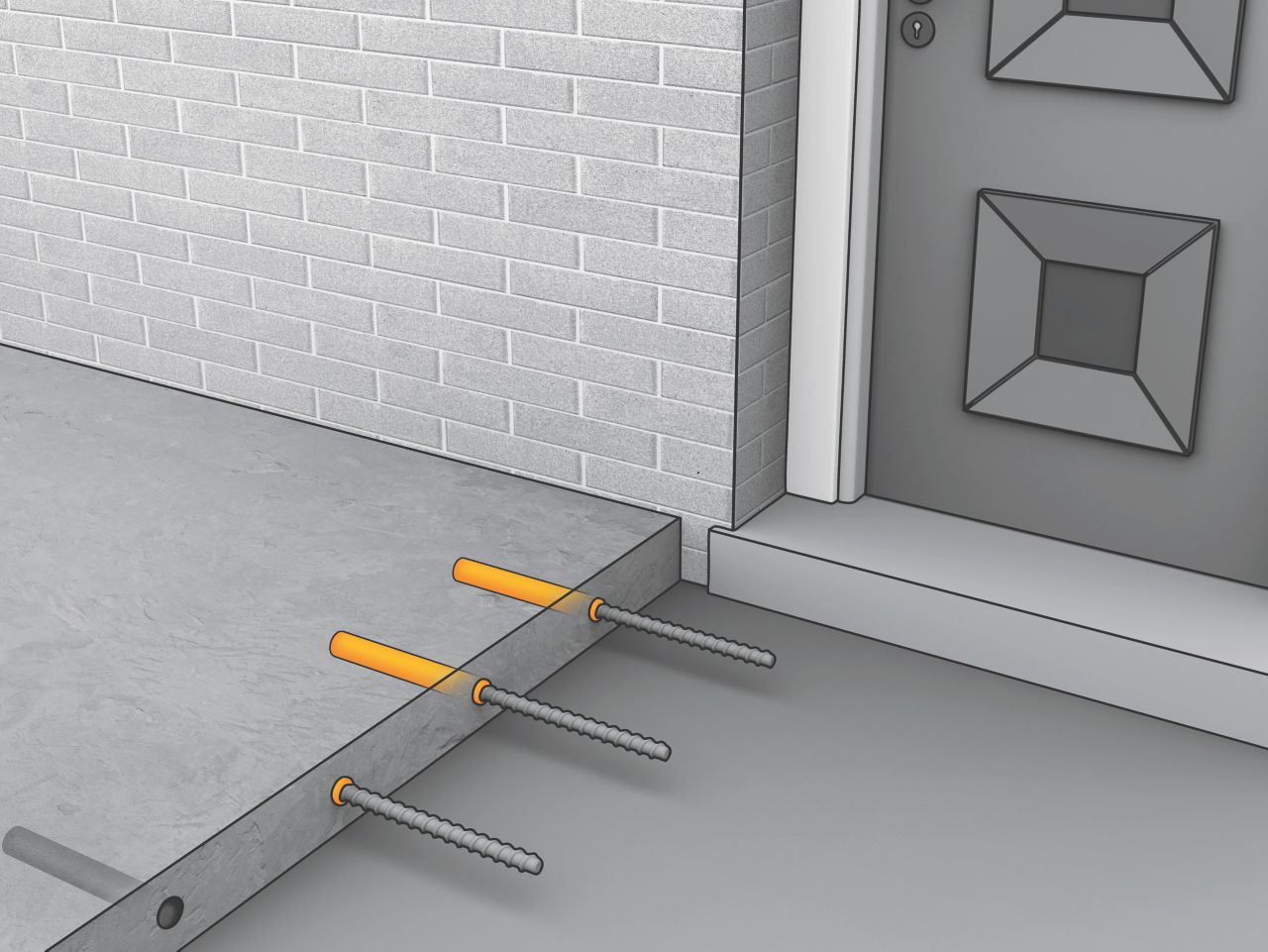

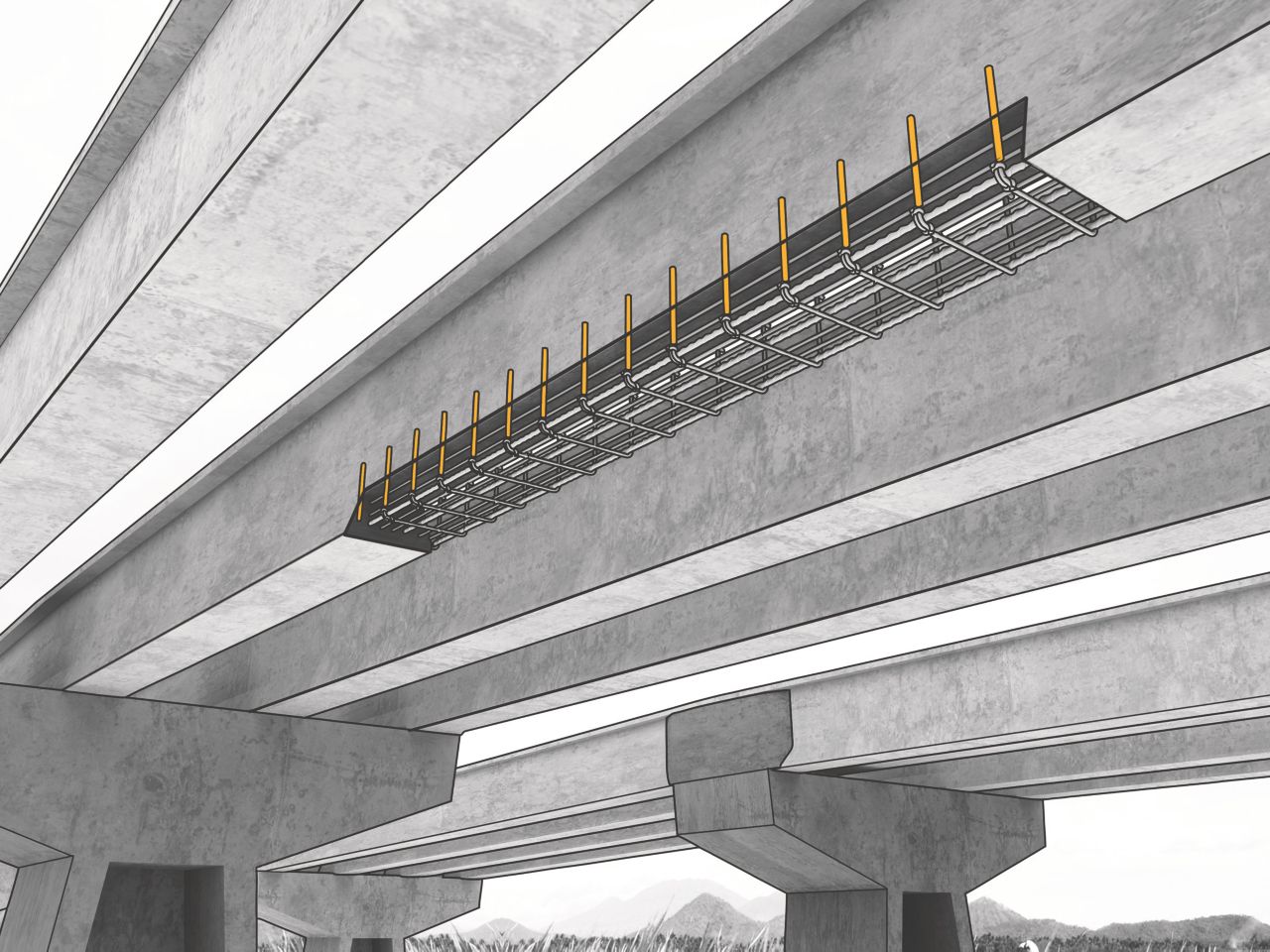

Chemical anchors are ideally suited for high load applications, as the resulting load is almost always stronger than the base substrate material itself. Since the system is based on chemical and mechanical compounds, no pre-loading stress is imparted to the substrate as it is with expansive mechanical anchors. Therefore chemical anchors are ideal for fixing close to edges and for close group anchoring.

Chemical Resin Anchors Offer Distinct Advantages over Mechanical Anchors

- Full resin embedding of the anchor

- Corrosion protection due to full embedding

- Improved cost performance

-

Higher flexibility

in terms of the bolt

length, depending on

the load

- No expansion – no cracking of substrate

- Keying effect – also holds in porous substrates

- Highly crosslinked duromer (a polymer which is crosslinked and will decompose when heated to a defined temperature) – which means it has outstanding load bearing capacity

Chemical Anchors Offer

Flexibility. What is

Possible?

- Anchors with close spacing

- Anchors with close edge distances

- Many anchor types available in different diameters and various drill hole depths

Application Examples